Dye penetrant testing across Brisbane, the Gold Coast, and Australia-wide

We test:

- Welds and fabricated structures

- Castings and forgings

- Storage tanks and pressure vessels

- Piping systems and plant equipment

- Structural steel components

Accurate surface inspection for welds and components

Dye penetrant testing provides a fast and effective way to identify cracks, porosity, and other surface flaws. By applying visible or fluorescent penetrants, our inspectors ensure defects are accurately revealed and reported for proactive maintenance and compliance.

Standards-based dye penetrant testing for regulated industries

Our dye penetrant testing is carried out in line with AS/NZS, ISO, API, and AWS standards. Detailed, audit-ready documentation supports compliance with statutory obligations, risk management processes, and maintenance strategies across regulated industries.

Our services support:

- Verification of weld and fabrication quality

- Compliance with industry and regulatory codes

- Maintenance planning and lifecycle management

- Documentation for regulators and third parties

Providing a comprehensive range of testing services

Explore additional testing solutions designed to keep your operations safe and compliant:

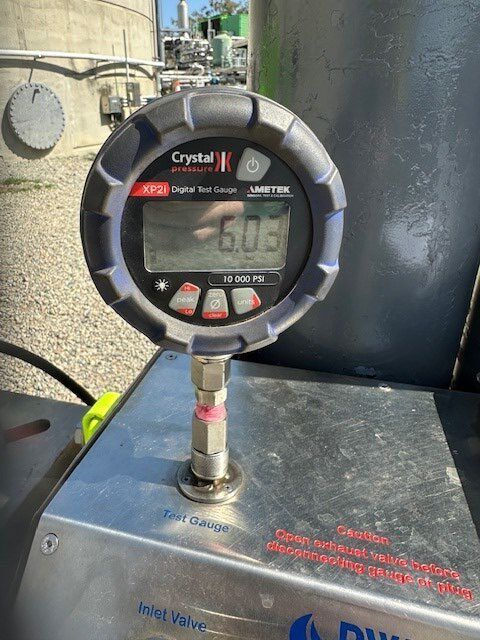

Accredited inspectors delivering reliable reporting

When you partner with Q-RIIMS, you gain access to ISO-accredited inspectors using calibrated equipment and proven DPI techniques to ensure defects are detected with precision. We deliver traceable, detailed reporting that helps asset owners make informed decisions while maintaining confidence in compliance and operational safety.

Identify cracks and flaws before they compromise safety with certified dye penetrant testing.

Contact Q-RIIMS today to arrange testing, request a quote, or schedule site support.

Mechanical and structural engineering services

- Fully qualified RPEQ engineer

- Development of detailed repair plans for pressure equipment and corroded/damaged structures

- Feasibility studies and concept development

- Project management

- Root cause analysis studies

- Finite element analysis (FEA)

- Full 3D modelling and drafting from concept through to manufacture-ready

- Full design and certification of:

- Pressure vessels

- Pressure piping

- Tanks

- Maintenance and access platforms

- Steel structures

- Lifting beams, jigs and associated lifting equipment

- Transport equipment

- Specialised tooling

- Hydraulic and pneumatic systems/machinery

Contact Us

We will get back to you as soon as possible.

Please try again later.

Arrange dye penetrant testing services today

Q-RIIMS delivers accredited dye penetrant testing with fast mobilisation, detailed reporting, and compliance-focused outcomes. Call our team or complete the form to book inspections, request a tailored quote, or arrange testing services for your site.

Locations we serve

From our Gold Coast base, Q-RIIMS delivers dye penetrant testing to industrial, mining, and energy operations across Australia. Our mobile teams provide efficient, certified testing with minimal disruption to plant and site operations.