Positive material identification (PMI) services across Brisbane, the Gold Coast, and Australia-wide

We test:

- Stainless steel and alloy piping

- Welded fabrications and components

- Pressure vessels and boilers

- Valves, flanges, and fittings

- Structural steel and castings

Material verification for compliance and quality assurance

Our PMI testing services confirm that materials match specified grades and are free from substitution or contamination. By identifying alloy composition on-site, we help asset owners reduce risk, ensure reliability, and maintain compliance with industry codes.

PMI services aligned with industry standards

All testing is performed in line with AS/NZS, ISO, ASTM, and API codes, ensuring accurate results and audit-ready documentation. Our PMI programs support compliance with statutory frameworks while providing confidence in material selection and performance.

Our services support:

- Alloy grade and composition verification

- Compliance with project specifications

- Prevention of material substitution risks

- Quality assurance and lifecycle management

Providing a comprehensive range of testing services

Explore additional testing services designed to maintain compliance and operational reliability:

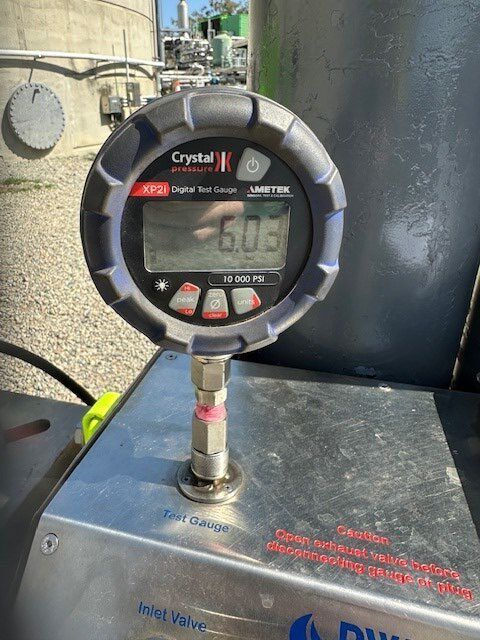

Certified specialists using advanced XRF technology

Q-RIIMS PMI testing is conducted by ISO-accredited inspectors using calibrated portable X-ray fluorescence (XRF) analysers. We provide fast, non-destructive results with clear reporting, giving operators confidence in both material compliance and operational safety.

Verify alloy composition and ensure compliance with certified PMI testing from Q-RIIMS.

Contact us today to arrange on-site testing, request a quote, or schedule inspection support.

Mechanical and structural engineering services

- Fully qualified RPEQ engineer

- Development of detailed repair plans for pressure equipment and corroded/damaged structures

- Feasibility studies and concept development

- Project management

- Root cause analysis studies

- Finite element analysis (FEA)

- Full 3D modelling and drafting from concept through to manufacture-ready

- Full design and certification of:

- Pressure vessels

- Pressure piping

- Tanks

- Maintenance and access platforms

- Steel structures

- Lifting beams, jigs and associated lifting equipment

- Transport equipment

- Specialised tooling

- Hydraulic and pneumatic systems/machinery

Contact Us

We will get back to you as soon as possible.

Please try again later.

Book positive material identification testing with Q-RIIMS today

Q-RIIMS delivers certified PMI services with detailed reporting and minimal disruption to operations. Contact us by phone or complete the form to request a tailored quote, organise on-site testing, or schedule inspection support for your facility.

Locations we serve

From our Gold Coast base, Q-RIIMS delivers PMI testing services to clients nationwide. Whether operating in metro plants or remote industrial facilities, our mobile teams provide responsive, certified testing tailored to your project requirements.